J P EXTRUSIONTECH LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to J P EXTRUSIONTECH LTD.

Tape Stretching Line With Tape Winders

Tape Stretching Line with inverter cheese winders:

For manufacturing PP/HDPE flat tapes, fibrillated tapes and serrated tapes to produce Woven sacks, Tarpaulins, FIBC's(Jumbo Bags), ropes, stitching threads, etc. & AC Inverter Driven Cheese Winders for HDPE/PP Woven Sacks.

Extrusion Coating Lines

For coating thin layer of polyolefin's (Mainly LDPE / PP) on substrates like Paper, Cotton Cloth, Woven fabrics, Jute fabric, Aluminum foil, BOPP film, Polyester film, etc. up to 5200 mm Web width applications.

Tandem Lamination Plant For coating Circular Woven fabric, for producing multi layer laminates up to 5 layers along with the various substrates like Paper, Aluminum foil, Polyester film etc.

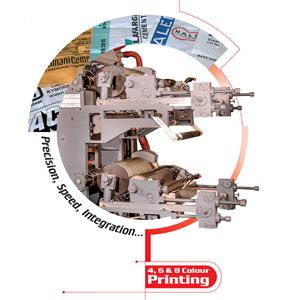

Printing Machines

High speed, PLC base 4/6/8 color flexo printing machine for Woven Sack having inline Corona Treatment, micro perforation, twist gusseting, cutting/winding system, for HDPE / PP laminated and un-laminated woven fabrics.

FEATURES:

- Turret Unwinder with Online Manual Splicing

- Specially designed Micrometric adjustment system provided at each Printing Station to have fine pressure from Anilox Roll to Printing Drum and from Printing Drum to the final product (Fabric). This will improve the better sharpness of Printing.

- Individual Gearbox system consists of hardened and ground oil dipped gears with the inbuilt planetary arrangement at each printing station. This increases the sturdiness of the machine which reduces maintenance and downtime.

- Online print registration adjustment provided in that gearbox for easy operation.

- Easy changeover for a change of direction of printing with the help of same gearbox system is also incorporated.

- Infeed and outfeed driven nip roll system to maintain constant tension of fabric for proper Print registration. It will not elongate the fabric or loosen the fabric between printing station.

- Anilox and Ink Rubber Rolls are of special design. This prevents splashing and scattering of Ink at higher operating speeds.

- Access to each printing station for ease of monitoring and cleaning.

- Operator Friendly and space-saving vertical gusseting unit.

- Control panel with PLC

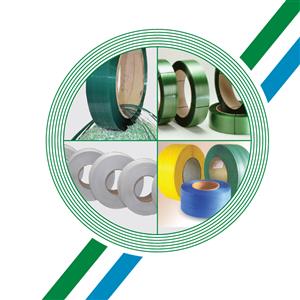

P. P. And Pet Box Strapping Lines

PET box strap line is suitable for 100% PET Flakes or PET Virgin Granules equipped with Dehumidified air dryer with Crystallizer.

PP Box strap line is suitable for fully automatic heat sealable straps having inbuilt single colour printing unit & two station embossing unit.

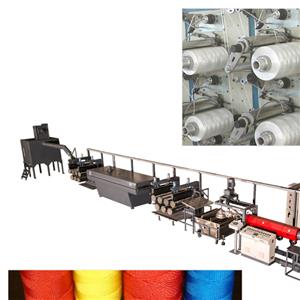

Monofilament Line

High output and outstanding quality Monofilament Lines

JPEL has in range of products highly efficient Monofilament Lines to produce HDPE / PP / Nylone Monofilament for manufacturing of :

- Ropes and Twines

- Tooth brush bristles

- Fishing Net

- Mosquito Net

- Doll hair & Wig hair

- Threads

- Knitting yarn

- Artificial grass

- Carpets

Salient Features :

- Extruder having L/D 30:1 for an output up to 250 Kgs./Hr. (Higher capacity lines also can be designed and supplied)

- Multi Strand Die

- Air knife.

- Goddets with Movack Design.

- 5 meter long orientation hot air oven, hot water bath.

Cheese winders for bunch winding.

JPEL has also supplied Jumbo Winders for winding of Monofilaments /Fibrillated tapes required for manufacturing ropes and FIBC - Jumbo bags.

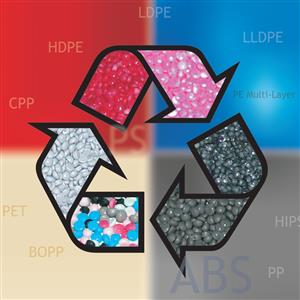

Multilayer Cast Film Line

Multilayer Cast Film Line:

Cast films produced on chill roll lines have become an indispensable product in the packaging industry. They provide versatile and high-quality options for safe and economic packaging of products.

To manufacture multi-ply packaging materials of 15 to 150 microns thickness, such as Stretch films, Cling films, Barrier films, Masking films, CPP films and Blister films.

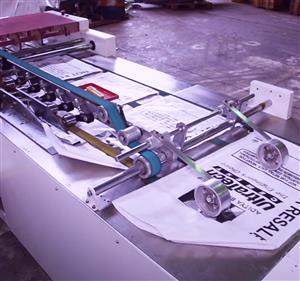

Bag Conversion Valvetech

ValveTech is the most modern conversion line with an advanced automation and control system that offers high productivity and efficiency with its indigenous design. It produces both side stitched bags with a valve at one corner of the bag.

The valve type bags are used in packing of various materials such as Cement, Salt etc. The material is filled through the valve using a hose and once the bag is filled the valve shuts automatically providing a locking system. ValveTech is best suitable for non-laminated woven fabric with an option for laminated fabric. ValveTech 35 model has the capacity to produce up to 35 Valve Type bags/min.

ValveTech conversion line, with servo & PLC control ensures high efficiency with minimal wastage and considerable savings in manpower & materials.

Bag Conversion Lines

JP developed Conversion lines for producing bottom folded and sewing woven sack made from a roll of tubular woven PP/HDPE fabric. JPBCL – 850 model from J P EXTRUSIONTECH LIMITED is a high-speed machine suitable for conventional bag application and is designed for cutting the tubular fabric, bottom folding, sewing, and stacking. This new generation machine with servo and PLC controls is designed for fabric width up to 850 mm and cut length up to 1400 mm with speeds up to 30 to 40 bags/min. Depending upon the material, width of the fabric, length of the bag, number of folds, stitches etc. This bag making machine is most appropriate for working with un-laminated fabric but can also be converted to use laminated fabric.

Advantages of this conversion Line:

- State of the art automated operation & consistent quality of end product (cut & sewn bags.)

- Reduced space requirement in finishing department for converting the roll of fabric to the finished bag.

- Reduced manpower requirement for producing the same quantity of bags.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.